Glossy Defects On The Surface Of The Injection Mold

There are many difficulties in Plastic Injection Molding. The injection mold consists of a movable mold and a fixed mold. The production of plastic products requires Injection Molding. The plastic material is injected into the mold cavity of the injection mold through an injection molding machine, and it is formed after cooling and solidification.

What should I do if there is a gloss defect on the surface of the plastic injection molding mold during the mold manufacturing process?

1. The mold finish is poor, the surface of the cavity has rust, etc., and the mold exhaust is poor.

2. The gating system of the mold is defective, the cold well should be enlarged, the runner, the polishing main runner, the runner and the gate should be enlarged.

3. The material temperature and mold temperature are low. If necessary, the local heating method of the gate can be used.

4. The processing pressure is too low, the speed is too slow, the injection time is insufficient, and the back pressure is insufficient, resulting in poor compactness and dark surface.

5. The plastic should be fully plasticized, but the degradation of the material should be prevented, the heating should be stable, and the cooling should be sufficient, especially for thick-walled ones.

6. Prevent cold material from entering the workpiece, and use self-locking springs or reduce nozzle temperature if necessary.

7. Too many recycled materials are used, the quality of plastic or colorant is poor, mixed with water vapor or other impurities, and the quality of the lubricant used is poor.

8. The clamping force should be sufficient.

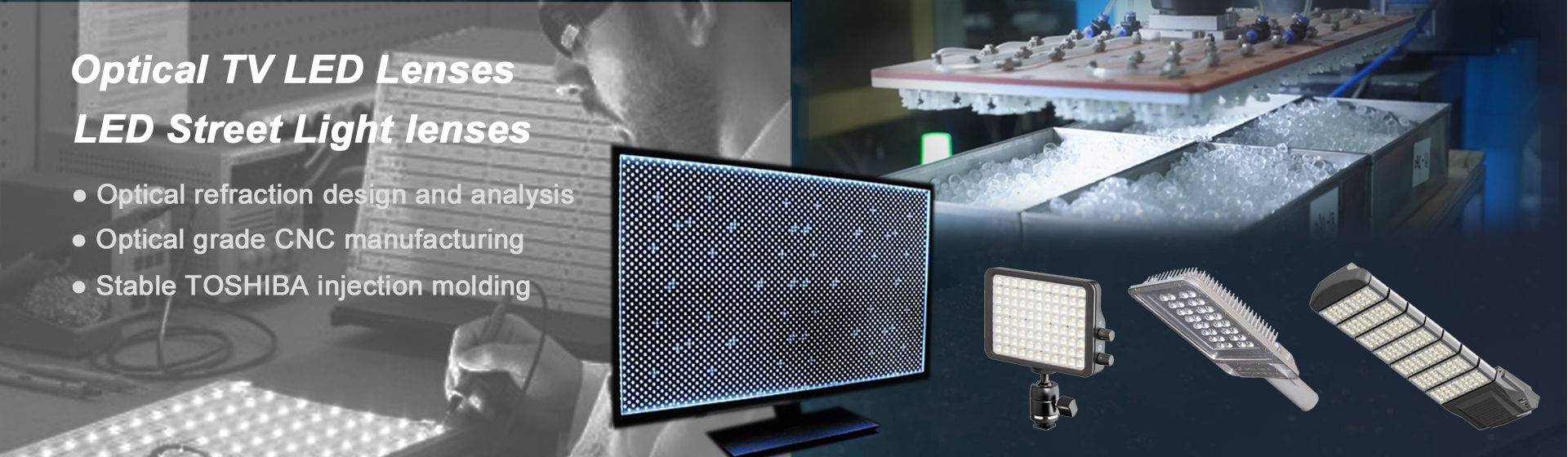

Our mould service includes: New project design, Product Development, 3D Print and rapid CNC Machining prototype, Assist in testing, Plastic Mould design and manufacturing, Injection molding OEM and assembly service. We are a professional plastic injection Mold Maker in mould OEM industry.