Aluminum Molding Alloy Precision Parts Processing Technology

Pure aluminum has low density, low melting point, high plasticity, easy processing, and can be made into various profiles and plates. Good corrosion resistance. Aluminum alloy is obtained by adding other metal elements to metal aluminum to obtain a metal alloy, such as silicon, iron, copper, copper, etc. The aluminum alloy obtained by adding other metals has the characteristics of low density, high strength, corrosion resistance, etc. Its light weight The characteristics of strength and strength make aluminum alloys widely used in the processing and manufacturing of various parts, and aluminum alloy parts are widely used in industry and life.

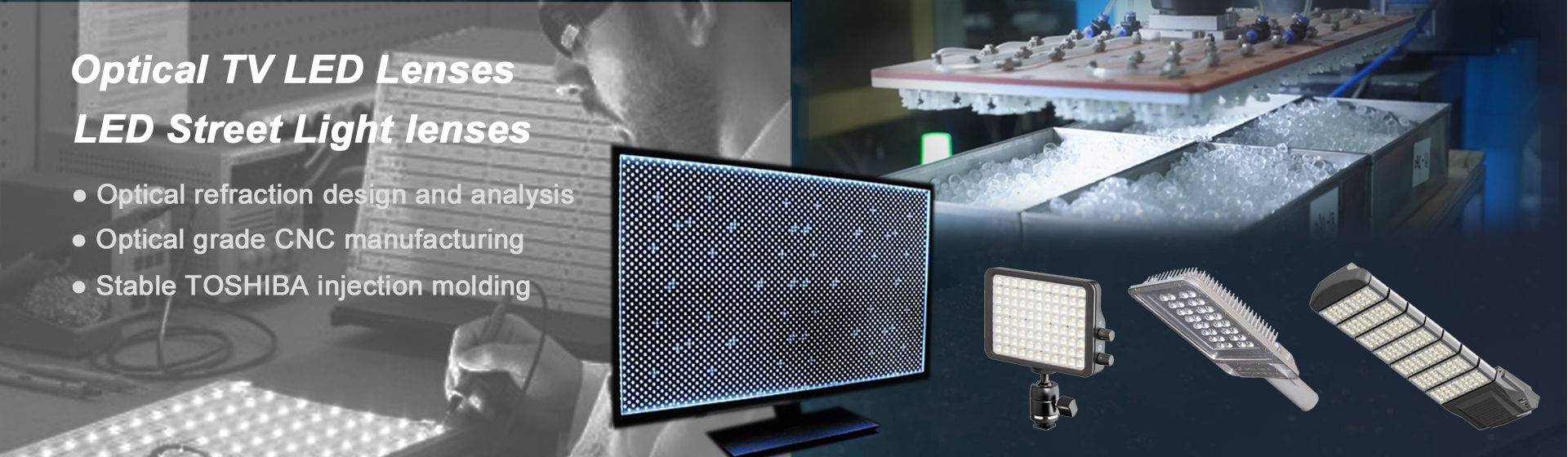

The wide application of aluminum alloy has promoted the development of aluminum alloy CNC machining technology, and the development of CNC machining technology has expanded the application field of aluminum alloy. Also known as CNC machining, automatic lathe machining, CNC lathe machining, etc., it is characterized by machining mold parts with general machine tools such as turning, milling, planing, drilling, grinding, etc., and then performing necessary fitter repairs and assembling into various molds; high precision requirements It is difficult to ensure high machining accuracy with ordinary machine tools, so it is necessary to use precision machine tools for processing; in order to make mold parts, especially punches with complex shapes, the processing of concave model holes and cavities is more automated, reducing fitters The workload of repairing requires CNC machine tools (such as three-coordinate Cnc Milling machines, machining centers, CNC grinding machines and other equipment) to process mold parts.

Cnc Cutting is a processing method that makes cutting more rational, and it is also a common process in precision machining of aluminum alloys. It adopts end mills with multi-directional cutting functions, helical cutting interpolation and equal-height cutting interpolation. Use as few tools as possible to machine a small number of holes. The unique advantage of CNC machining of aluminum alloy precision parts is that the ball end mill combined with the helical interpolation method can continuously process the taper hole; the ball end mill and the helical interpolation drill can be used for boring and chamfering. Machining; end mills combined with equal-height plunge interpolation can perform semi-finishing and precision parts processing on holes; end mills used for thread processing can be combined with the spiral offset method to process various threaded holes.

With the development of material science, the advancement of manufacturing technology, and the wide application of aluminum alloys, the requirements for the processing quality of aluminum alloy precision parts are getting higher and higher, and the application of CNC machining technology for aluminum alloy precision parts is becoming more and more extensive. , People's requirements for the CNC machining quality of aluminum alloy precision parts are also getting higher and higher. Therefore, further research and development and improvement of CNC machining technology and equipment for aluminum alloy precision parts have become the top priority and direction of the aluminum alloy precision machining industry.

Our mould service includes: New project design, Product Development, 3D Print and rapid cnc machining prototype, Assist in testing, Plastic Mould design and manufacturing, Injection Molding OEM and assembly service. We are a professional plastic injection Mold Maker in mould OEM industry.