Analysis Of Development Trend Of Sheet Metal Industry

China's position in the middle of global Sheet Metal Manufacturing will be further quiet. With the acceleration of China's integration into the global economic environment and the rapid rise of economic strength, China has become a very dynamic economic region in the world. China's economic facilities are relatively complete, its industrial development is relatively mature, and its labor costs are relatively low. It has the comparative advantage of becoming the middle of the global sheet metal manufacturing industry, and the sheet metal manufacturing industry has obvious characteristics of export-oriented development. The strengthening of intermediate positions is first manifested in the overall growth of the export of hardware products in recent years: the export growth rate of main sheet metal products is higher than the growth rate of output, and higher than the growth rate of sales in the domestic market; the main sheet metal products are in full bloom, Not only did the traditional export products such as electric appliances, hand objects and building hardware products have a high growth rate, but also the export growth rate of Kitchen Appliances and bathroom products, which had a small proportion of exports in the past, was also very obvious in 2004. The huge market and the attraction of intermediate jobs will further attract the transfer of sheet metal multinationals' manufacturing intermediates to China.

Competition among sales channels is also increasing. Due to the oversupply of domestic sheet metal kitchen and bathroom products and the increasing pressure on quality, sales channels have become one of the competitive components of the link, and the competition for channels has become increasingly fierce. On the one hand, kitchen appliance manufacturers have strengthened the control of retail terminals, tried to reduce sales links, save sales prices, and make sales channels develop in a professional direction, and corporate sales models are developing in a direction that can adapt to various markets at the same time. On the other hand, the development trend of the sales industry has led to a continuous rise in the positions of large-scale home appliance chain stores, and the ability to control the industry has increased, participating in and triggering the price competition that was mainly dominated by manufacturers in the past. With their broad market coverage, purchasing scale and cost advantages, large retailers will have increasing control over production enterprises in terms of product pricing and payment delivery.

Corporate polarization will further intensify. The next few years will be a period of vibration in the sheet metal industry. The simple result of this high-speed vibration will lead to the expansion of the trend of polarization in the current sheet metal kitchen and bathroom brand camp. It is expected that there will not be so many sheet metal companies that can really survive in the market in the next few years. This high-speed vibration in the sheet metal industry will bring huge opportunities, and the result of the vibration will make the market operation more rational.

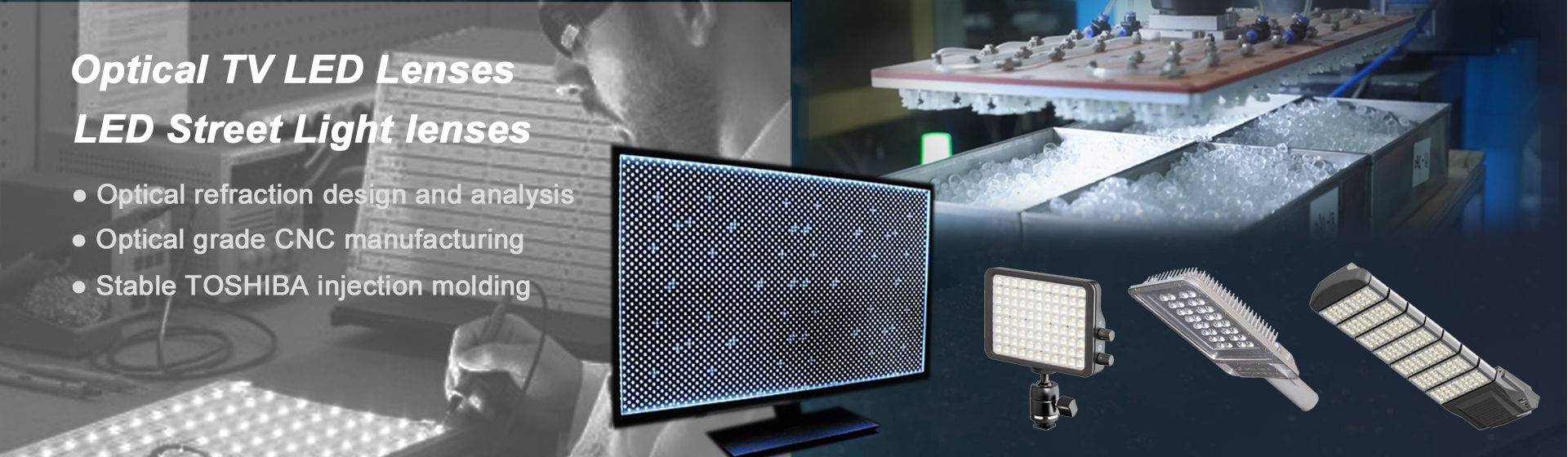

Our mould service includes: New project design, Product Development, 3D Print and rapid CNC Machining prototype, Assist in testing, Plastic Mould design and manufacturing, Injection Molding OEM and assembly service. We are a professional plastic injection Mold Maker in mould OEM industry.