How To Improve Sheet Metal Processing Technology?

Everyone is engaged in Sheet Metal Processing. If you want to get a high salary in the platform, you must improve your sheet metal processing technology if you want to live well. If you are technically solid, you can get a high salary wherever you go. Although it is hot to say, everyone must put in diligence and practical behavior to improve the mediation of connections.

Related sheet metal processing, its production and processing steps are to plastically deform a small amount of metal sheet according to hand-made or stamping processing, and make it into the desired shape and specifications, which can be further produced according to electric welding or a small amount of machine processing. Produces more cumbersome parts. So how can we improve this technology?

1. (Sheet metal processing of sheet metal chassis) Special objects, fixtures and product workpieces cannot be placed on the top of the CNC lathe and its transmission. Strip-shaped chips and long chips in sheet metal processing that occur in the drilling environment must be dealt with as soon as possible with a hook, and cannot be pulled for a long time.

2. Scientific research on the variation specification of component strain force and limitation in the whole process of sheet metal processing plastic deformation and forming, select suitable blanks and effective intermediate blank shapes, so as to optimally reach the shape required by components. Research on the impact of sheet metal processing specifications such as temperature and strain rate on the plastic deformation production and processing resistance of metal materials and the techniques for developing metal material durability and reduction resistance to obtain components with advanced benefits.

3. At the earliest, the surface of sheet metal processing must be washed with water to eliminate the waste on its surface. Then add soap, liquid detergent or a 5% ammonia solution in water to scrub. Carefully carry out dipping again with water.

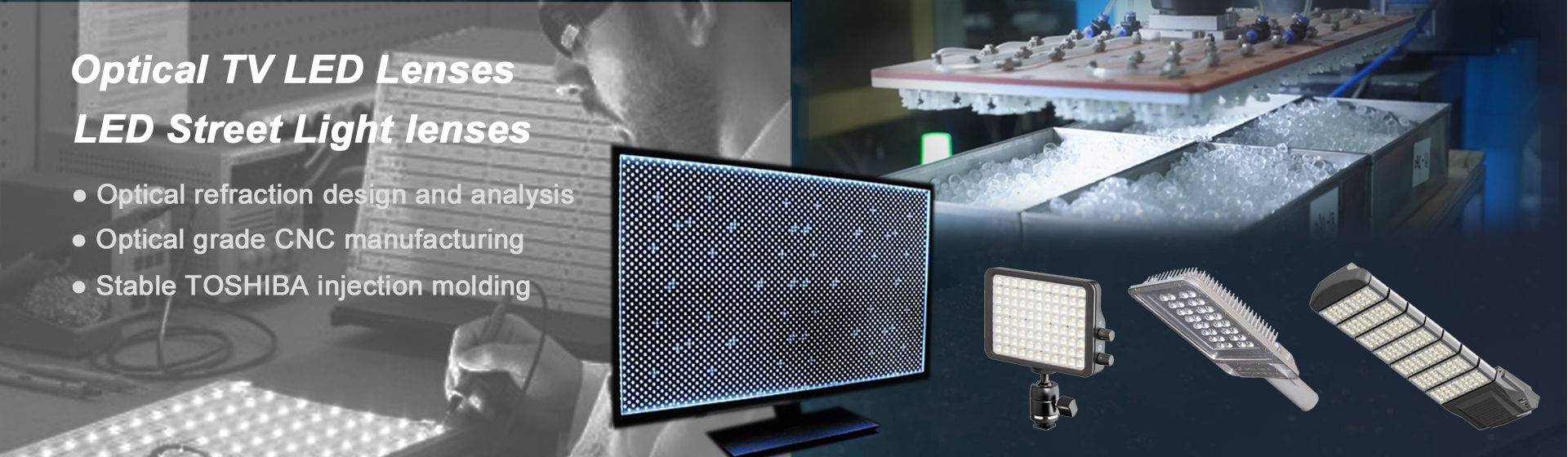

We are a professional electronic hardware company. It has the craftsmanship of Rapid Prototyping and large-scale CNC Machining. Professionally provide different Injection Molding Service. There is also the service of Sheet Metal Processing, which can customize different processing parts for you. Plastic Mold of various materials, processed and built.