News

Sheet Metal Processing - Material Requirements

Sheet Metal Processing In automobile manufacturing and maintenance, the shape of many sheet metal structural parts is very complex. In order to prevent the difficulty of the sheet, the sheet metal material must have good process performance requirements, namely:

1 The material in sheet metal processing must have good plasticity. It must have the ability to be permanently deformed without being destroyed under the action of external force. For cold-worked parts, there must be good cold plasticity, such as stamping parts for automobile parts; for hot-worked parts, there must be good thermoplasticity, such as hot forging spring steel plates, hot rivets, etc.

2. Good weldability for sheet metal processing. Many automotive sheet metal parts are welded together by spot welding, oxygen welding, arc welding or gas maintenance welding, so the required sheet metal parts must have good welding performance. This is particularly important in the repair and maintenance of automobiles. Materials with good weldability have high welding strength and small cracking tendency.

3 Sheet metal processing is cheap and economical. For any component of the car, economics should be considered under the condition that the working conditions are met. Those that can use ferrous metals, do not use non-ferrous metals; those that can use non-ferrous metals, never use precious metals. The life of automobile sheet metal components should be compatible with the life of other components of the automobile.

4. Good chemical stability for sheet metal processing. Most of the automotive cover parts work in the open air, often in contact with water and steam, especially like mufflers, which often work at higher temperatures and corrosive gases. This requires sheet metal parts to have good chemical stability, not only requiring corrosion resistance at room temperature, strong rust resistance, but also not being corroded or deformed under high temperature or sun exposure.

1 The material in sheet metal processing must have good plasticity. It must have the ability to be permanently deformed without being destroyed under the action of external force. For cold-worked parts, there must be good cold plasticity, such as stamping parts for automobile parts; for hot-worked parts, there must be good thermoplasticity, such as hot forging spring steel plates, hot rivets, etc.

2. Good weldability for sheet metal processing. Many automotive sheet metal parts are welded together by spot welding, oxygen welding, arc welding or gas maintenance welding, so the required sheet metal parts must have good welding performance. This is particularly important in the repair and maintenance of automobiles. Materials with good weldability have high welding strength and small cracking tendency.

3 Sheet metal processing is cheap and economical. For any component of the car, economics should be considered under the condition that the working conditions are met. Those that can use ferrous metals, do not use non-ferrous metals; those that can use non-ferrous metals, never use precious metals. The life of automobile sheet metal components should be compatible with the life of other components of the automobile.

4. Good chemical stability for sheet metal processing. Most of the automotive cover parts work in the open air, often in contact with water and steam, especially like mufflers, which often work at higher temperatures and corrosive gases. This requires sheet metal parts to have good chemical stability, not only requiring corrosion resistance at room temperature, strong rust resistance, but also not being corroded or deformed under high temperature or sun exposure.

5.The dimensional accuracy and intrinsic quality of a well-processed sheet. The dimensional accuracy and intrinsic quality of the sheet affect sheet metal processing. The noise is great, especially for the molded parts.

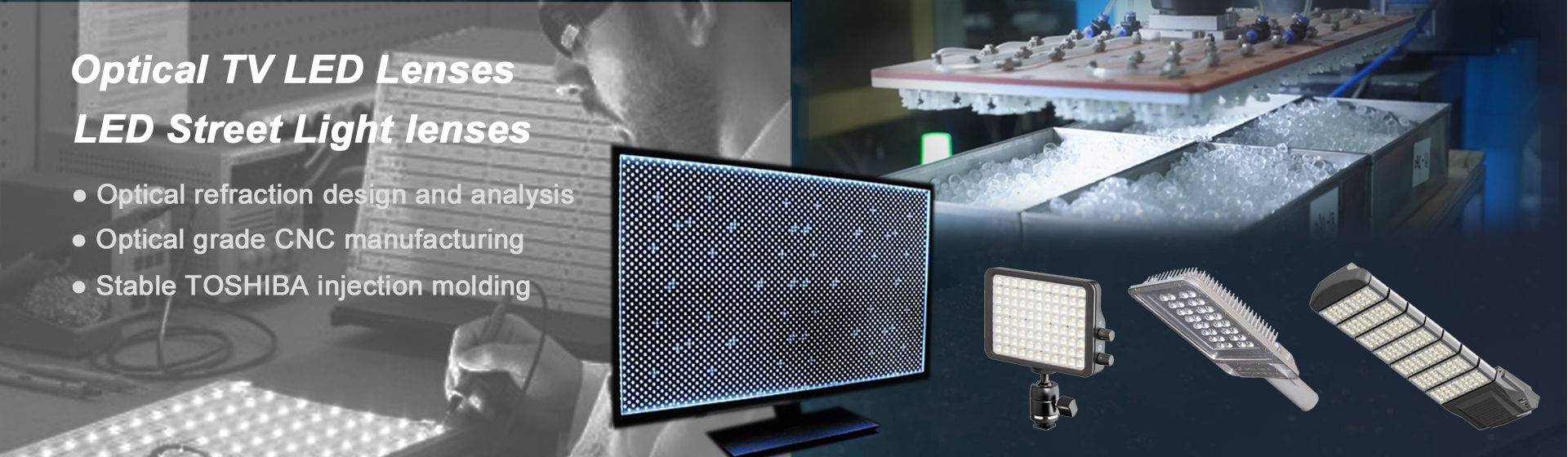

The above is about sheet metal processing. There are many other interesting stories and developments in our company, as well as sales of Product Development, Mold Maker, Rapid Prototype, Plastic Mould, 3D Print and Plastic Injection Molding. You can click and have a look. , you can consult us if you are interested.