Sheet Metal Processing Steps And Tools

In fact, plate processing can also be called metal processing in general. The specific application examples mainly refer to: using plates to make some utensils commonly used in daily life, such as: plates, iron drums, oil pots, etc., the first plate processing The first process is to use a little plate, riveting, bending the edge, welding, winding forming, etc. However, according to the difference in the layout of the sheet, the detailed size of the sheet is also different.

Sheet metal work: The first is to carry out the overall planning of the sheet metal parts → the second step is to make drawings according to the detailed technical requirements of the sheet metal workpieces → the third step is to punch the sheet metal workpieces → the fourth step is to punch the sheet metal workpieces. →The fifth step is to punch the sheet metal workpiece →The sixth step is to punch the sheet metal workpiece →The sixth step is to punch the sheet metal workpiece →The seventh step is to perform surface processing of the sheet metal workpiece →The seventh The first step is to process the surface of the sheet metal workpiece, such as: punching of the sheet metal workpiece → the eighth step is to perform the drilling processing of the sheet metal workpiece.

Sheet metal processing tools

The entire machining process of sheet metal must use a series of polishing tools, so preparations must be made in advance before the first work. According to the installed Chiba knife or stainless steel bowl brush, the installed Chiba knife can be used for polishing of welding spatter, grinding of surface bumps and scratches, grinding of welding misalignment, and grinding of misalignment in production and processing. Go and wait for the work; install a stainless steel bowl brush, which can perform welding polishing, the main advantage of which is to remove the oxide scale in the welding area. The polished welding topcoat must not have defects such as cracks, welding scars, burn-through, arc craters, and sand holes.

After welding, there should be no post-welding blowholes, welding flashes, pits, cracks, scratches, electric solitary scratches, etc. Excessive deep bruises, production and processing errors in narrow indoor spaces, and one-sided precision sharpening, etc. The installation of sandpaper wheels can realize indoor bruises and arc bruises that cannot be achieved by polishing machines.

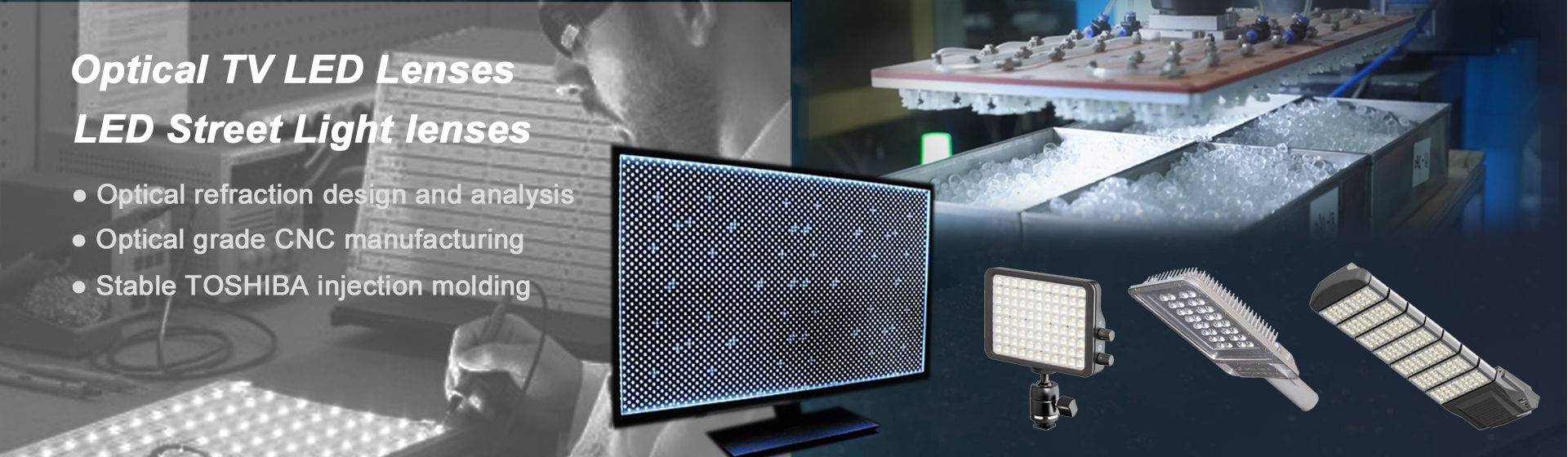

Our mould service includes: New project design, Product Development, 3D Print and rapid CNC Machining prototype, Assist in testing, Plastic Mould design and manufacturing, Injection Molding OEM and assembly service. We are a professional plastic injection Mold Maker in mould OEM industry.